Products Overview

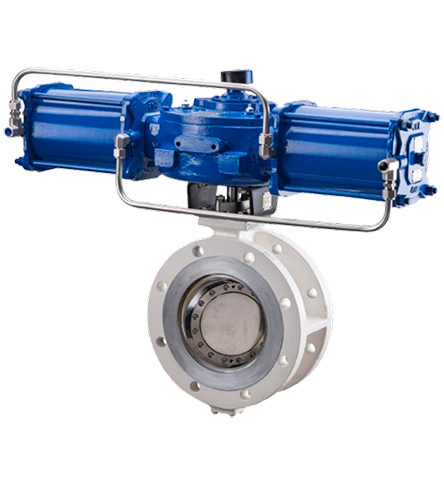

Actuators & Accessories

Durable electric and pneumatic actuators, paired with essential accessories, for complete and dependable automation solutions.

Ball Valves

Tight-sealing, high-strength valves built for critical isolation and control in high-pressure, high-cycle operations.

High-Performance Butterfly Valves

Double-offset design delivering precise shut-off in demanding pressure and temperature conditions.

Resilient Seated Butterfly Valves

Compact, adaptable valves designed for efficient flow regulation across a range of industrial applications.

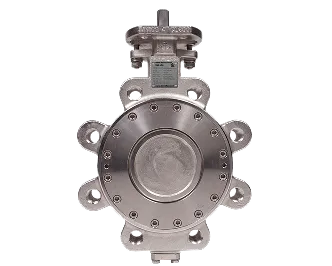

Triple Offset Valves (TriO™ Series)

Zero-leak, metal-seated valves engineered for absolute shut-off and control in applications where reliability is non-negotiable.

Material Test Reports Portal

The Material Test Reports Portal provides a clear view of every DelVal product’s material history. From raw material sourcing to final delivery, records are maintained in real time, enabling teams to confirm compliance, streamline audits, and make informed operational decisions.

Heat Number Traceability:

Follow the complete material lineage from supplier to plant.

Chemical Analysis:

Confirm elemental composition and mechanical properties for assured quality.

Pressure Test Records:

Access hydrostatic and pneumatic test results with actual measured values.

NDT Reports:

Access radiographic, ultrasonic, and dye penetrant inspections against defect detection.

Certification Documents:

Retrieve third-party inspection reports and compliance certificates instantly.

Heat Number Traceability:

Follow the complete material lineage from supplier to plant.

Chemical Analysis:

Confirm elemental composition and mechanical properties for assured quality.

Pressure Test Records:

Access hydrostatic and pneumatic test results with actual measured values.

NDT Reports:

Access radiographic, ultrasonic, and dye penetrant inspections against defect detection.

Certification Documents:

Retrieve third-party inspection reports and compliance certificates instantly.2D/3D Product Configurator

From concept to installation, every project starts with a clear engineering vision. Our 2D/3D Configurator guides that vision into precise, actionable designs, giving engineers clarity and confidence at every step, whether for new installations or system upgrades.

By combining expert guidance with field-proven validation, the Configurator provides a seamless engineering experience and helps plants achieve predictable, dependable results.

How It Works:

.1 Define Parameters:

Set process conditions, spatial limits, and performance requirements.

.2 Visualize in 3D:

Visualise 3D components assembly, confirming fit and alignment.

.3 Validate & Export:

Ensure compatibility and download ready-to-use CAD files.

"The configurator helped reduce valve sizing errors for our team and even validated our selections based on our use-case and industry applications."

- Plant Manager, Petronas